Industrial Systems by American Industrial Sales, LLC

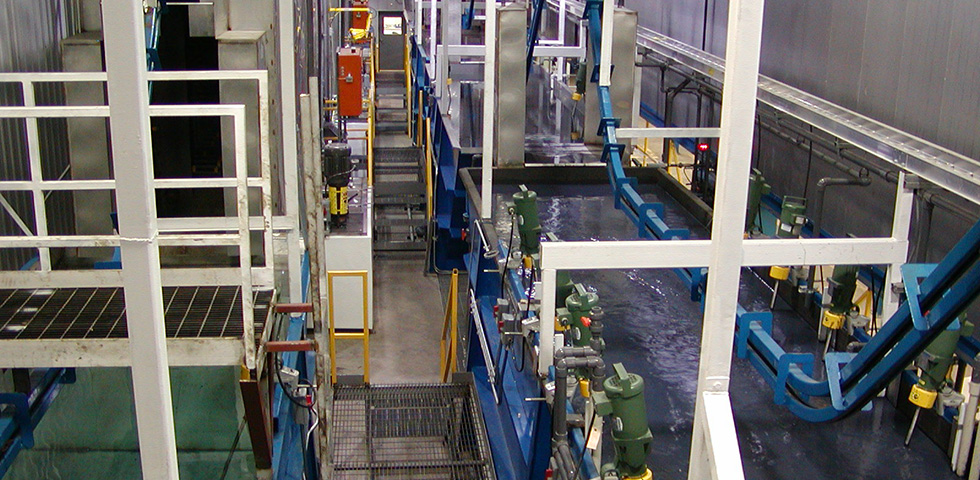

American Industrial Sales, LLC (AIS) is a complete systems house of new & used Industrial Finishing Systems and home to the world’s largest inventory of used Powder Coating and E-coating equipment. We have more than 20 years of experience in the design, manufacture, and installation of finishing systems including powder coating, liquid coating and electrocoating. We offer our customers new systems, refurbished systems, removal, relocation and upgrading services for existing equipment. In our time in business, we have provided our services and systems to a large variety of companies throughout the Northern Hemisphere. At AIS, we take into account important factors such as product size, production rates, product handling, energy efficiency, floor space, and budgets in order to provide the fastest and best design layouts, systems, and delivery times in the industry. We pride ourselves in supplying quality equipment at a competitive price with on-time delivery.

Browse through our site and contact us with any questions. Call at 920.361.5208 (toll free at 877-503-3303) or send us your comments/questions using our simple online form. Thanks for checking us out on the web!

Nick Thoma

President